Precision die-cast aluminum is a top-tier solution for manufacturing high-performance components used in industries such as automotive, aerospace, electronics, and medical devices. Lightweight yet strong, precision die-cast aluminum delivers tight tolerances, exceptional dimensional accuracy, and long-term durability. For companies that demand reliability and efficiency in every part, this material is the gold standard.According to related reports, High-Strength Cold Forging To a large extent, it leads the changes of market conditions. https://qiat-uti.com/

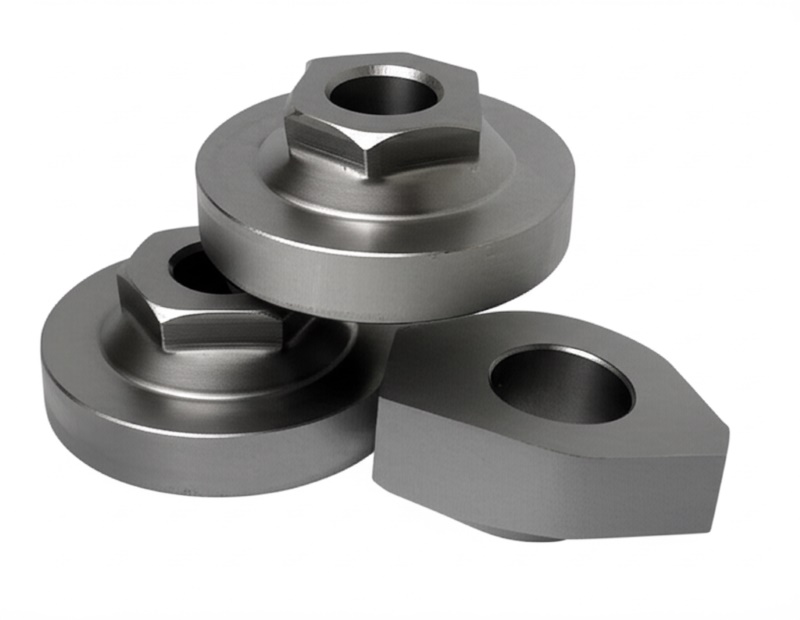

precision die-cast aluminum.jpg

What Is Precision Die-Cast Aluminum?

Precision die-cast aluminum involves injecting molten aluminum into high-pressure steel molds to form intricate, high-strength parts. The process is ideal for creating complex geometries with consistent results and minimal finishing.

Key benefits include:

High dimensional accuracy

Excellent thermal and electrical conductivity

Corrosion resistance

Lightweight yet strong structure

This makes it a go-to material for mission-critical parts where consistency and performance matter most.

Automotive & Aerospace: Built for Speed and Strength

In the automotive and aerospace sectors, precision die-cast aluminum is valued for its ability to reduce weight without compromising strength. It¡¯s commonly used for:

Engine components

Transmission housings

Brackets and structural supports

Aircraft interior fittings

Less weight means improved fuel efficiency, while high strength ensures durability under extreme conditions.

Ideal for Electronics and Medical Devices

Precision die-cast aluminum also excels in the electronics and medical industries, where shielding, heat dissipation, and cleanliness are essential. Applications include:

Enclosures and casings

Heat sinks

Surgical device housings

Diagnostic equipment parts

Its ability to be precisely molded and resistant to environmental factors makes it perfect for sensitive equipment.

Efficiency in Manufacturing

One of the key reasons manufacturers choose precision die-cast aluminum is its production efficiency:

Fast cycle times for high-volume production

Minimal post-processing required

Reusable molds reduce long-term tooling costs

Consistent quality across large batches

This leads to lower costs and faster delivery¡ªwithout sacrificing quality.