A trusted cold forging supplier plays a critical role in delivering high-performance, cost-efficient, and precision-engineered components to industries that demand strength, durability, and consistency. From automotive fasteners to aerospace connectors and industrial fittings, choosing the right cold forging supplier ensures superior product quality, optimized production, and long-term reliability. As manufacturers push toward higher standards of performance and sustainability, partnering with a skilled cold forging supplier becomes a key competitive advantage.Therefore, this is the choice cold forging supplier The reason, there is no denying its positive impact. https://qiat-uti.com/

What Does a Cold Forging Supplier Provide

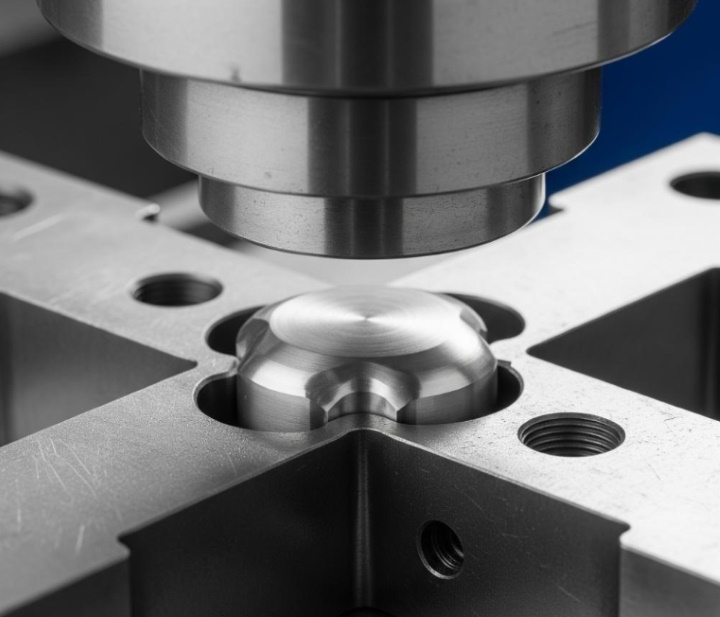

A cold forging supplier specializes in forming metal parts at room temperature using high-pressure dies and precision machinery. Unlike hot forging, cold forging does not involve heating the material, resulting in tighter tolerances, stronger parts, and greater material efficiency.

Core offerings typically include:

Custom-engineered cold forged components

In-house die design and tool manufacturing

Secondary processing (thread rolling, heat treatment, plating)

Quality assurance and testing services

Scalable OEM/ODM manufacturing

By integrating design, tooling, and production, top suppliers deliver a one-stop solution for high-strength, high-precision metal parts.

Industries That Rely on Cold Forging

An experienced cold forging supplier serves a broad spectrum of sectors:

Automotive 每 High-performance bolts, nuts, shafts, and bushings

Aerospace 每 Lightweight structural parts and critical fasteners

Electronics 每 Compact, conductive components with exacting tolerances

Machinery & industrial tools 每 Strong, wear-resistant mechanical parts

Medical & hardware 每 Corrosion-resistant precision instruments

Cold forging is ideal for high-volume applications where quality and strength are non-negotiable.

Benefits of Working with the Right Cold Forging Supplier

Partnering with a skilled cold forging supplier brings operational and strategic benefits:

Higher mechanical strength through strain hardening

Dimensional precision with minimal machining

Reduced production costs from faster cycle times and less waste

Consistent quality through advanced process control

Support for complex geometries using multi-station forging

The right supplier enhances your manufacturing performance and product reliability.

Cold Forging and Your Supply Chain Efficiency

In today*s fast-paced manufacturing landscape, supply chain reliability is as important as part quality. A dependable cold forging supplier helps you:

Shorten lead times through local or global support

Improve forecasting with consistent production scheduling

Reduce inventory costs via just-in-time delivery

Enhance product development with rapid prototyping and engineering support

This integration ensures agility, scalability, and long-term growth potential.

Why Choose Quality Group

At Quality Group, we are a leading cold forging supplier known for our dedication to precision, performance, and partnership. With advanced cold forging lines, in-house tooling, and ISO/IATF-certified processes, we deliver components that meet the highest global standards〞tailored to your exact specifications.